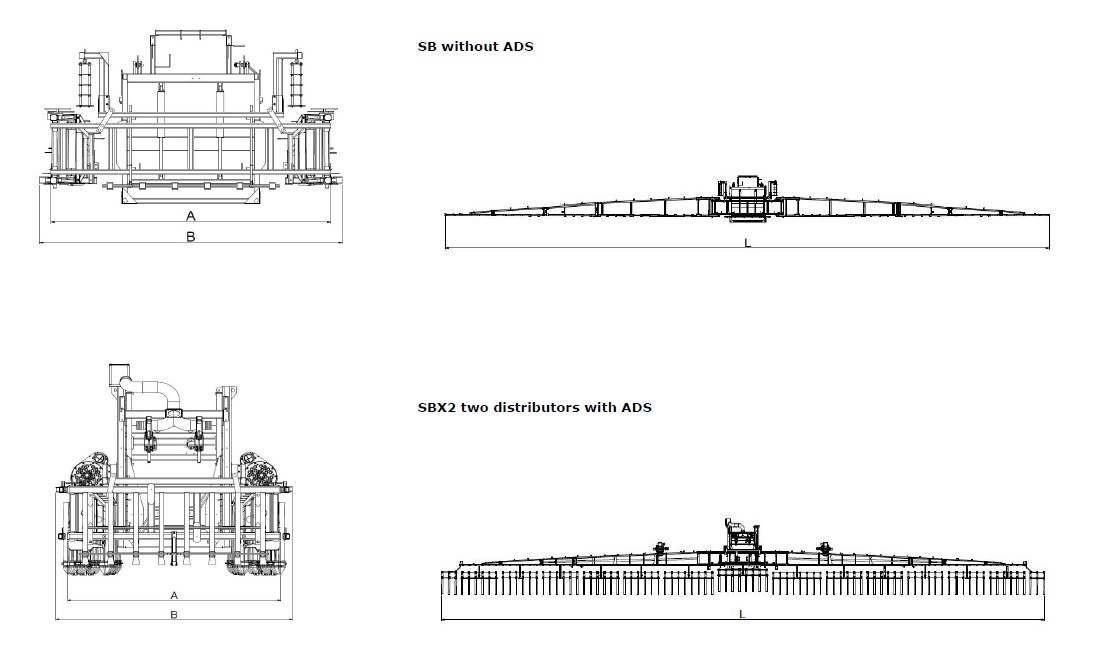

SB 16 m (12-16) folded at 12 m

With ADS, spilt manure on the road is history. The system is controlled with hydraulics and closes off the hoses completely, so that they do not drip during transport. Our drip hose booms from have a master/slave cylinder system which ensures that the boom folds in and out at the same time.

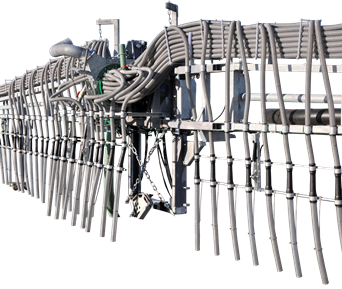

The drip hose booms are fully galvanised and built with a trapezium suspension which ensures that the boom always follows the surface of the ground, even on hills.

The boom is raised and lowered hydraulically, and when the boom is folded along the sides of the slurry tanker during transportation, it is inclined, so that the slurry runs back to the distributor and does not drip from the hoses.

Find more information about the key features of the product.

Long life time

• Strong vertical SAMSON AGRO distributor

• All the steel on the drip hose booms is galvanized

• The distributor is equipped with a stone trap that collects foreign objects so they are not causing unnecessary wear on the distributor and avoiding potentially serious damage

• The boom can be folded and raised. It reduces the risk of damage to the boom when the slurry tanker leaves the field

• SBX and SBX2-models are of a particularly strong construction. They have an extended working life

High efficiency

• All drip hose booms are fitted with vertical distributors. A vertical distributor has a higher capacity than a horizontal one. This results in a shorter emptying time and an increased output per hectare

• The dosage can be adjusted inside the tractor cabin with the control system before driving. The dosage can also be changed while driving if necessary. This saves time

• The drip hose booms can be hydraulically folded from the tractor cabin using the control system. A time saving feature

• The Stone trap contributes to reduced operating stops

Optimal application of the slurry leads to an optimal yield

• The distributor and cutting knives inside it ensure an accurate dosage of slurry across the booms width

• Trapezoidal Suspension with the addition of a controlled override, ensures a uniform distribution of slurry independent of the terrain

• The dosage can be changed when driving, thus the dosage may for example be reduced in low-lying areas in the field where large quantities of slurry may tend to run down

Low energy consumption (fuel)

• High capacity, less operating time per hectare for less fuel consumption

Low maintenance costs

• Drip hose booms are made of strong, practical and treated materials, which increases the durability

• The stone trap removes foreign objects that may damage the distributor

• X-models are designed for heavy duty. This reduces maintenance costs