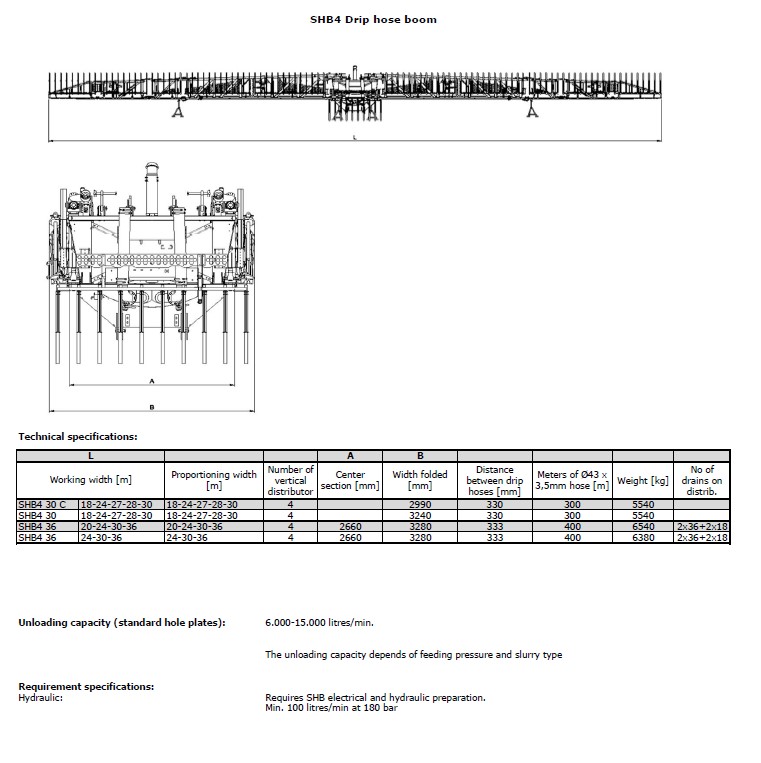

SHB4 36 m (24-30-36) folded at 24 m

SHB4 36 m (24, 30, 36) folded at 24 m is designed for the user who wants great flexibility on the application width.

In transport mode, the boom folds at 24 m and can therefore only be mounted on PG II 35 with pump tower or SAP1.

The boom is mounted very closely to the rear of the slurry tanker, which optimises weight distribution and pressure on the drawbar eye of the tanker when the boom is in the working position.

The four slurry distributors reduce the length of the slurry hoses significantly. The feed hoses to the distributor are routed inside the boom construction. The slurry hoses are secured in the hose guides so they line up neatly in a row without buckling up and down. This ensures that the hoses empty more quickly and that they run completely empty.

The two large side wings are hinged at the bottom of the frame and controlled by a large hydraulic cylinder at the top. Quite uniquely, this means that the boom can be adjusted both above and below level in relation to the central frame. So you can adjust the boom at any time so the slurry hoses follow the terrain and remain in contact with the soil. The boom is fully integrated with SlurryMaster 8000.

The side wings are folded in two layers using a planetary gear driven by an oil motor. This provides fully controlled and optimised rotation of the pivot joint and minimises the need to lubricate moving parts. A new hydraulic system allows the oil motor to cut out upon impact to avoid damage to the boom.

The boom is less than 3.3 metres wide in the transport position – even on the very large slurry tankers with a 2.2 metre diameter tank – as the slurry hoses are located inside the boom and the boom is folded in only two layers for road transport.

Find more information about the key features of the product.

The boom is less than 3.3 metres wide in the transport position – even on the very large slurry tankers with a 2.2 metre diameter tank – as the slurry hoses are located inside the boom and the boom is folded in only two layers for road transport.

It never exceeds 4.0 metres in height. So despite the size, the boom does not take up much room on the road.

The Dual Pass Application (DPA) allows the driver to adjust the working width so the boom only applies slurry to the outer 6 metres on each side.

This is then topped up with another pass on the remaining 18 metres on a SHB4 30 or 24 metres on a SHB4 36 boom, increasing the application range per load. This can be an advantage on very hilly terrain. This method of applying slurry also reduces mess in the tracks.

DPA also allows several slurry tankers to work together to achieve a high application capacity on 30 or 36 m track. Combining one or two slurry tankers with 18 or 24 m booms together with a slurry tanker with a SHB4 30 or SHB4 36 boom will achieve an extremely high capacity on large farms that use 30 or 36 m tramlines.

This means that many agricultural contractors will be satisfied with one SHB4 boom and still ensure that large quantities of slurry will be applied at exactly the right time.

When unfolding near field boundaries and roads, FBS provides an ideal solution that eliminates unfolding over the desired working width.

This allows the operator to drive up the first track alongside roads or boundaries to unfold the boom. This minimises unnecessary pressure damage to plants and soil and increases the efficiency of the machine set.

FBS is standard on all SHB4 versions.

The slurry is distributed via four vertical distributers. This gives a rapid response to the start /stop operation, as there are less than 400 metres of slurry hose on the SHB4 36 m boom and 300 m on the SHB4 30 m boom.

SAMSON slurry distributors are known to be extremely efficient with a high capacity, low wear and good lateral distribution.

The four distributers are equipped with their own slide valve, so each of the four sections can be closed off.

The control system automatically adjusts the dosing of slurry for the new working width when a section is turned on or off. The improved opportunity for closing off individual sections reduces the overlap of slurry into wedges on the fields. This also reduces the risk of lodging.

The fully integrated control system SlurryMaster 8000 allows you to adjust, monitor and control both the slurry tanker and SHB4 down to the smallest detail.

With the SlurryMaster 8000, the slurry tanker and boom appear as a single unit, where the amount of slurry is adjusted according to the driving speed and the working width.

The two large side wings are hinged at the bottom and controlled by a large hydraulic cylinder at the top. Quite uniquely, this means that the boom can be adjusted both above and below level in relation to the central frame.

So you can adjust the boom at any time so the slurry hoses follow the terrain and remain in contact with the soil. This reduces volatilisation as much as possible, because the slurry is applied in narrow grooves on the soil surface and with the least possible contact with the air. If the slurry hoses are not in contact with the soil, the slurry will splash over a larger soil surface, causing increased volatilisation.

The side wings are folded in two layers using a planetary gear driven by an oil motor. This provides fully controlled and optimised rotation of the pivot joint and minimises the need to lubricate moving parts.

A new hydraulic system allows the oil motor to cut out upon impact to avoid damage to the boom.

All SHB4 drip hose booms are equipped with vertical distributors with cutting discs and stone traps.

On the SHB4 drip hose booms the stone traps are equipped with slide valves to easier empty the distributor. The slide valve opens automatically, when the boom is folded for transport. In this way the distributors are always empty before driving on the road and thus avoiding the possible spillage of slurry.

Optimal application of the slurry leads to an optimal yield

• Four distributors for accurate dosage of slurry

• Possible to close off four sections for reduced overlapping

• Side wings can be adjusted individually both above and below level, so that the slurry hoses always follow the terrain

High efficiency

• Computer controlled folding and unfolding boom

• Four distributors with high capacity

• DPA for an efficient and gentle application strategy

Flexibility as desired

• Quick change of the working width via hydraulic folding and unfolding

• Optimised for application at 30 m or 36 m with few working widths for simple and robust construction

or

• Optimised for high flexibility with several working widths for supporting different tramlines

Long life time

• Galvanized frame in high-strength steel

• The side wings are folded in two layers using a planetary gear driven by an oil motor

• Gentle folding and unfolding via computer-controlled regulation

Low maintenance costs

• Built in stone trap in distributors

• Optimum placement of the slurry hoses protected in the frame

• Simple construction with few moving parts