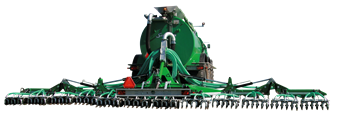

TD 12

The TD makes it possible to inject slurry without compromising on capacity. This is equipment for the future oriented agricultural contractor.

The TD injector with double disc cutter is designed for injection in grass on heavier or clayed soil types. Both injectors are supplied with a rotational suspension which counteracts the stress on the cutter during turning. They have a hydraulic system for individual depth regulation which ensures a uniform and constant injection depth.

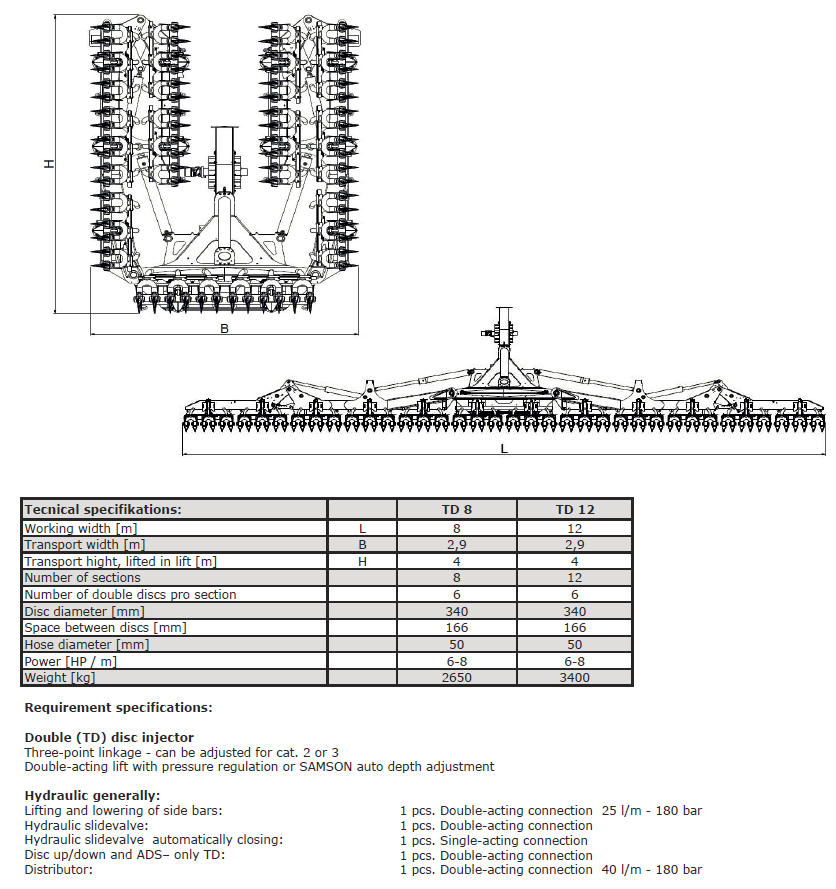

The TD injector is available in both a 8m and an 12m version.

Find more information about the key features of the product.

Long life

• The double cutting discs are designed to sharpen themselves, providing a longer working life

• The powerful special hubs with double bearings are very durable

• Shims between the hub and discs can be removed gradually, depending on the wear of the cutting discs. This extends the life of the discs

• Small weight compared to other similar injectors

• Optimal lubrication is provided through the central lubrication system. This leads to reduced maintenance and longer life

High efficiency

• The double cutting discs allows a flexible depth adjustment and creates a ”suction effect” when making the furrow for the placement of slurry at the plant roots. Injecting reduces the evaporation of the nutrients in the slurry and increases its utilization

• The double cutting discs can also work in heavy or dry soil types

• With the addition of the hydraulic gate valve, the stone trap can be emptied without the driver having to leave the tractor, saving the drivers time

• With the fitting of the automatic closing mechanism for the hydraulic gate valve, the gate valve is automatically closed after opening. This eliminates the risk of slurry being accidently delivered

Optimal spreading of slurry – optimal yield

• The individual cutting disc sections which were developed in collaboration with the University of Aarhus, Research Centre Foulum, ensures flexibility when cornering. Each section follows the grounds contours, even at higher speeds. There ensures an uniform injection, even when cornering and on uneven terrain

• Due to pressure through a closed hydraulic system acting on the cutting discs, the precise placement of the slurry in the soil is possible. This provides the most effective use of the slurry and less risk of slurry having direct contact with the plants

• When selecting hydraulic depth control (with the SAMSON AGRO control computer SlurryMaster 6000) there is a precise placement of the slurry in the furrows, even with varying soil conditions. This increases the utilization of the slurry

• With a hydraulic weight transfer of max. 5000 kg, the injection equipment has sufficient weight to penetrate into the soil, even if the soil is hard, dry and difficult. This makes the injection season longer, with a better utilization of the injector

• The anti-drip system prevents overdosing on field edges and the soiling of the road

Low maintenance costs

• The double cutting discs are self-sharpening

• The powerful special hubs withstand harsh environments, so there is minimal maintenance required

• Shims extends the life of cutting discs, they can be used for many hectares before replacement is required