TE

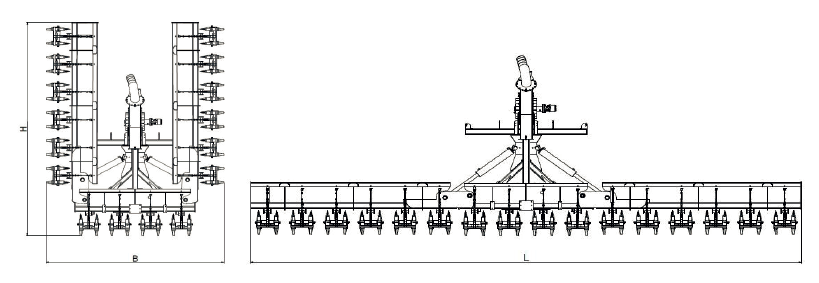

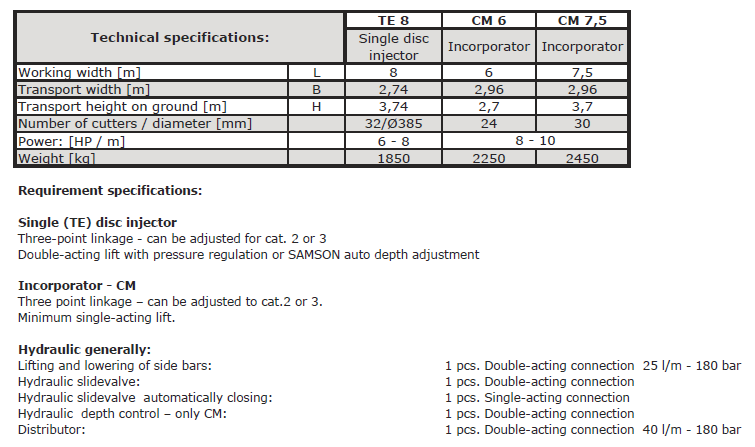

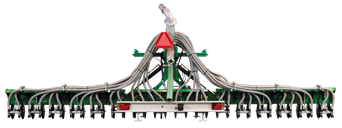

The TE injector with cutter has been developed to inject slurry in grass and fields with growing crops respectively on light or clayed soils. It is available in 8m working width.

The TE injector has a hydraulic system for individual depth adjustment that ensures a constant incorporating depth. It has a single disc cutter for injection of slurry in grass and seeding fields on light soils. It is supplied with a rotational suspension which counteracts the stress on the cutter during turning. They have a hydraulic system for individual depth regulation which ensures a uniform and constant injection depth.

TE comes in 8m working width.

Find more information about the key features of the product.

Long working life

• The frame is of a strong construction

• Adjustable suspension reduces wear on the cutting discs

• There is less wear on the cutting discs and bearings for injectors with a single disc

• The distributor is equipped with a stone trap, stones and other foreign objects can be quickly disposed avoiding possible damage to the distributor

• Individual cutting disc pressure accumulator reduces the load on the main frame.

• Central lubrication ensures better maintenance

High efficiency

• The design of the distributor leads to a secure and flexible dosing from 4 to 30 t/ha. Or even higher - depending on the driving speed

• SAMSON AGRO centrifugal pump ensures a high slurry pressure in the distributor, which ensures stable and precise dosing

• The self-sharpening blades in the distributor improves the ability to chop straw and other organic materials in the slurry, ensuring a more homogeneous and “easier to run out mixture” in high dosages

Optimal spreading of slurry – optimum yield

• Flexible depth adjustment means less damage to the growing crops

• The distance between the cutting discs ensures optimal use of slurry

• The dosing is a very accurate with the yields being consistent all over the field

• Hydraulic weight transfer allows you to work even if the ground is hard, dry or tough. It prolongs the injection season

• Individual pressure on each cutting disc ensures that the slurry is injected. This reduces the risk of the slurry being placed on top of the plants. Reducing the risk of infection and increasing the utilization of the nutrient content in the slurry

• Movable suspension reduces possible damage to plants

Low energy consumption (diesel)

• Single cutting discs requires less traction

• Due to the design of the distributor with the flow centrally located, less energy is required as the cup cutter does not have to rotate as fast in order to achieve a high performance.

• The hydraulic depth adjustment ensures optimal utilization of energy compared to a system using a constant pressure

Low maintenance costs

• The injector is produced from high quality materials

• Minimal maintenance is required during operation

• Parts are readily available and easy to obtain

• Individual cutting disc pressure accumulator reduces the load on the frame and thus reduces the need for maintenance

• Movable suspension reduces wear on the cutting discs

• Distributor with cup cutter disc and central lubrication reduces the need for maintenance