FLEX II 20E

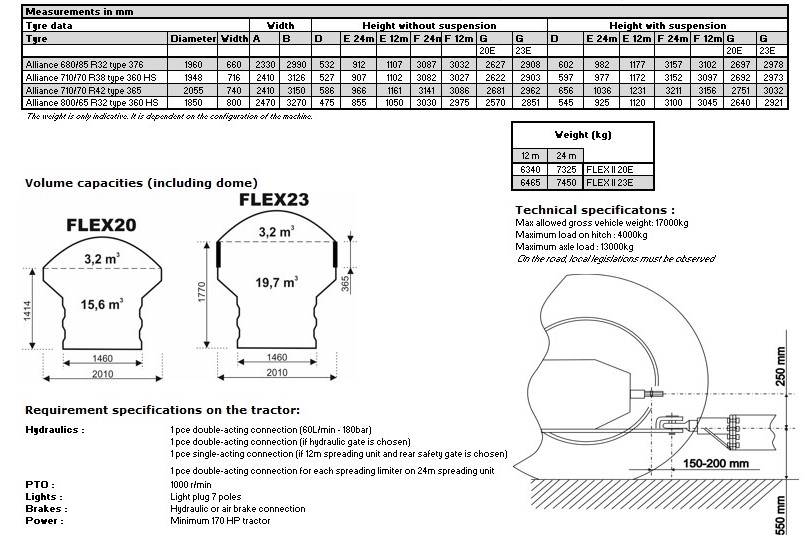

FLEX II 20E is a single axle spreader with a volume of 20 m3.

FLEX II 20E has the same box structure as the existing FLEX series. The box has a tapered length to ensure uniform distribution of the material to the spreading equipment, which is important for an

even spread pattern in the direction of travel.

The FLEX II is constructed from high-strength Domex steel which offers high strength with a low net weight.

FLEX II 20E is equipped with manual floor chain adjustment as standard, but can be upgraded to MuckControl, SpreadMaster 6500 or SpreadMaster 8500.

FLEX II 20E can be equipped with load cells, which permits both static or dynamic weighing. This gives a very precise dosage, regardless of the material.

Find more information about the key features of the product.

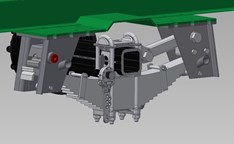

This is a all round spreading system for all types of material. Constructed with two vertical rollers and hinged mallet - mounted deflectors. The 12 meter system can handle quantities from 4 t/ha up to 70 t/ha.

The 12 meter spreading system is equipped with a gearbox manufactured by SAMSON, which is known throughout many years for its extreme durability and reliability.

A double Rübig flat link chain ensures a regular feed to the spreading device. The Rübig chain is made of high tensile steel and is driven by a powerful motor. The drive is possible in both directions. The chain links are extremely wear resistant, with an impressive long working life and low maintenance costs. The self-cleaning L-shaped carriers cover 95% of the box bottom area. The automatic hydraulic chain tensioner always ensures that the tension is suitable for the spreading material, thus extending the life of the chain. The ease of use and the regulated tension guarantees low maintenance costs, with high resistance to wear and tear.

SpreadMaster 6500 runs the carpet speed proportional to the driving speed of the spreader. It ensures a more precise dosage of the material.

All important functions are shown and can be operated on the main screen of the 4,3" touch screen.

SpreadMaster 6500 can also run load sensing.

Volumetric dosage

SpreadMaster 6500 can as an option be upgraded to do volumetric dosage.

The system adjusts the speed of the carpet floor according to the height of the dosage gate, the driving speed and the set dosage per hectare. This gives a very accurate dosage in especially homogenous, high value materials like chicken manure, compost or lime.

Jobs can be exported

SpreadMaster 6500 counts the area, time, loads and the theoretical weight of the material that has been spread. The information can be exported on an USB stick or SD-card as screen dump.

The SpreadMaster 8500 controller can control the entire machine and can be operated both with buttons and via a touch screen. SpreadMaster 8500 can handle weighing on the FLEX II and dose the spread volume based on the actual weight in the box – in other words, dynamic weighing, which is weighing while spreading. A field map/application map can be uploaded to the controller, so the dosage can be controlled by these. For example, this may be in relation to the spreading of lime based on soil samples or the spreading of poultry manure based on the application map for nitrogen.

SpreadMaster 8500 can also handle a simple weighing system, in which a given volume is weighed when stationary in order to calibrate the volumetric system – static weighing.

SpreadMaster 8500 is ISOBUS-compatible. The operating system can therefore be operated via the tractors own terminal if this also is ISOBUS-compatible.

FLEX II can be equipped at the factory with a central lubrication system from German company Beka. The system features a Beka Pico pump with a 1.5 litre reservoir. SAMSON is the only spreader manufacturer that can offer this pump with stirring inside the reservoir. The pump has a strong aluminium pump housing, while the distributors and fittings are made with a special alloy for longer lifetime. The central lubrication ensures that all lubrication points are lubricated frequently and with the right amount. This provides optimal lubrication, less maintenance, longer machine durability and a higher resale value.

Long Life

• The case and the rollers are made from Domex S600 steel and have a high tensile strength.

• Triangle is suspended with maintenance-free shock absorbers

• The roller tines are made from special hardened steel.

• Many SAMSON AGRO spreaders have been in use for over 20 years.

• The FLEX II spreader is fully welded. Spot welding is not used.

• 4 extremely robust floor chains from Rübig ensures minimal chain wear. The tensile strength of each chain is 12.5 tons.

• The gearbox chain for the 24 meter spreading system is housed in a closed chain cover and coated with lubricant.

• There is a shock absorber between the rollers and gear box.

High Efficiency

• The position and the angle of the spreader rollers, their rotation speed (534 rpm), but also the size of the blades and rotation speed as well as the position of the deflectors on the spreading table ensures an extremely rapid spreading of the materiel. This means that more loads can be made on a daily basis from this spreader.

• The extremely low construction of the machine ensures a low center of gravity and thus high driving stability. This enables faster driving speeds over the field and on the road. Again this leads to the possibility for more loads each day

Optimal use of nutrients optimum yield

• The position and the angle of the spreader rollers, their rotation speed, the size of the blades and their rotation speed as well as the position of the deflectors on spreading table ensures that the material becomes pulverised and uniformly spread.

• Depending on which material is to be applied, you can choose betweeen 12 meter and 24 meter spreaders. If it is heavy organic materiel, a 12 meter spreading system is the better option, and for lighter materials such as compost or chicken manure the 24 meter spreading system should be selected.

Low Energy Consumption (diesel)

• The case is made of Domex S600 steel, which reduces the overall weight of the spreader, so that the tractor uses less power.

• The box is made as a self-supporting construction, with which an underlying chassis can be avoided, thus reducing the machine's own weight.

• The wheels of the machine are mounted on the side, which enables the usage of large diameter wheels and thus a lower rolling resistance on the wheels, which means that the tractor requires less horsepower.