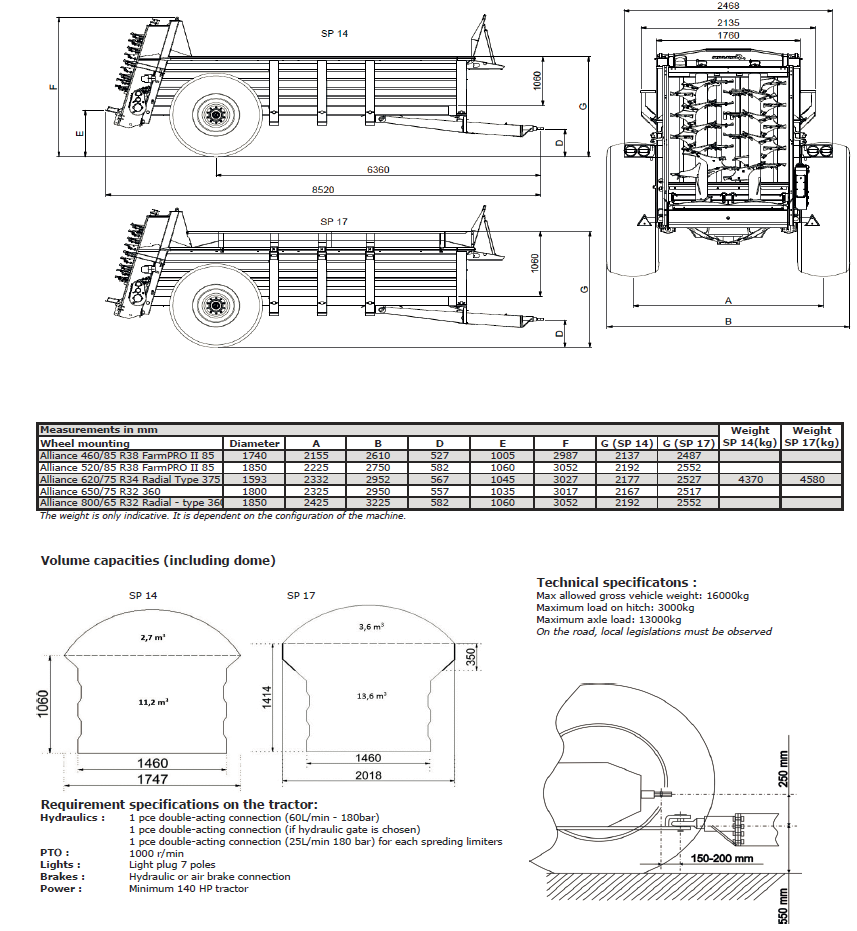

SP 17

All SP-Spreaders are fitted with double, vertical beaters. These were designed in collaboration with end users for the application of heavy and compact materials. Therefore the SP-concept is an excellent choice for high amounts of output. The spreader can be fitted with a fixed lower deflector as well as a distribution device for lighter materials. The low tractive effort required leads to reduced fuel consumption, making the spreaders very economical to use.

As is the case with all our equipment, the SP-Spreaders are produced using high strength steel. Which ensures extreme robustness with low weight. The linear conical designed box of the SP-Spreader is unique. It guarantees a natural flow of the spreadable material to the spreading device ensuring optimal output rates. The inside top width of 2m gives an impressive load capacity. The front side is fitted with a wide mesh grid, allowing good visibility for the driver.

Find more information about the key features of the product.

As is the case with all SAMSON AGRO equipment, the SP-Spreaders are produced using high strength steel. Which ensures extreme robustness with low weight. The linear conical designed box of the SP-Spreader is unique. It guarantees a natural flow of the spreadable material to the spreading device ensuring optimal output rates. The inside top width of 2m gives an impressive load capacity. The front side is fitted with a wide mesh grid, allowing good visibility for the driver.

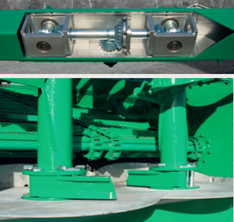

A double flat link chain ensures a regular feed to the spreading device. The chain is made of high tensile steel and is driven by a powerful motor. The drive is possible in both directions. The chain links are extremely wear resistant, with an impressive long working life and low maintenance costs. The self-cleaning L-shaped carriers cover 95% of the box bottom area. The automatic hydraulic chain tensioner always ensures that the tension is suitable for the spreading material, thus extending the life of the chain. The ease of use and the regulated tension guarantees low maintenance costs, with high resistance to wear and tear.

As the world’s first manufacturer of spreaders with double vertical beaters, SAMSON AGRO has invested its experience in the construction of equipment for the optimal and uniform distribution of solid organic fertilizer. The construction of the beaters allows spreading rates from 4 ton to 70 ton per hectare. This is based on a unique concept of the beaters, with the winding gradient in the first lower third being reversed. Through use of the powerful mobile mounted deflectors the material is perfectly distributed, with exposure to wind minimised. The formed and twisted knifes of hardened steel also provide optimum resistance to wear and tear.

The high-performance monoblock triple housing gearbox exclusively manufactured by SAMSON AGRO, delivers an extremely high rotational speed to the beaters enabling excellent shredding of the material. The integrated elastic couplings guarantee that foreign objects are transferred safely. The large amount of oil ensures a constant high performance as well as natural cooling. It also helps to prevent the formation of cracks and ensures an exceptionally long life.

A hydraulic gate can be mounted on all SAMSON spreaders. The hydraulic gate is galvanized and prevents waste from falling of the spreader during transport. Furthermore, the slurry gate functions as a proportioning mechanism during spreading of pulverized and highly concentrated materials. As an extra option a level indicator can be attached.

SpreadMaster 6500 runs the carpet speed proportional to the driving speed of the spreader. It ensures a more precise dosage of the material.

All important functions are shown and can be operated on the main screen of the 4,3" touch screen.

SpreadMaster 6500 can also run load sensing.

Volumetric dosage

SpreadMaster 6500 can as an option be upgraded to do volumetric dosage.

The system adjusts the speed of the carpet floor according to the height of the dosage gate, the driving speed and the set dosage per hectare. This gives a very accurate dosage in especially homogenous, high value materials like chicken manure, compost or lime.

Jobs can be exported

SpreadMaster 6500 counts the area, time, loads and the theoretical weight of the material that has been spread. The information can be exported on an USB stick or SD-card as screen dump.

Long working life

• Proven and solid construction

• High Strength steel is used in the construction of the SP series

• Fully welded seams, without exception

• Cutting knives made from hardened steel that is extremely resistant to wear and tear

• Exclusive and unique to SAMSON is the monoblock triple housing gearbox that ensures a long working life

• High safety with the integrated elastic couplings

• Long working life. Many SP-Spreaders are still in use after 20 years of operation

• Double flat link chain. For a more regulated feed - dual directional rotation of the chains - low maintenance costs

• High-quality workmanship - double-layer polyurethane coating

Extreme efficiency

• Perfect stability with a low centre of gravity - faster transportation and increased profitability

• Large wheel dimensions and reduced power requirements

• Low loading height – faster loading and increased productivity

• Application angle of the beaters – intelligent design

• Optimal beater diameter and rotational speed

• Comfortable to drive

• User friendly with a complete selection of accessories

Optimal spreading

• Unmatched output performance

• Excellent shredding capabilities, precise spreading pattern

• Linear conical box design offers unique advantages for better flow of the materials towards the spreading device

Versatility, suitable for all materials

• Double vertical beaters from SAMSON with the winding gradient in the first lower third of the beaters being reversed, delivering unmatched spreading consistency

• Extremely constant distribution of the spreadable materials with low exposure to wind

• Robust gear motor with a spreading capacity of 4 to 70 tons per hectare

• Safety during transport and no material falling on the road due to the use of the hydraulic back gate

Reduced fuel consumption

• Lower weight and therefore reduced power requirements

• Improved power transmission allows the use of larger wheels and reduces rolling resistance

Our experience - your advantage

• SAMSON has over 65 years of experience in the business of spreading organic fertilisers

• SAMSON was the worlds first manufacturer to build spreaders with double vertical rolls