FAP

With a focus on efficiency, safety and design, the new Front Arm Pump (FAP) is setting a new standard for front fill systems.

Filling starts using a vacuum from the ejector on the tanker, which primes the reliable centrifugal pump on the front fill system.

The centrifugal pump then continues the high capacity filling operation without using a vacuum.

The FAP system makes it easy to fill the slurry tanker directly from the transport tanker.

Driving in headlands and crop damage are reduced significantly, as you drive directly to the transport tanker. The implement on the back of the slurry tanker can also remain in the working position, thereby increasing efficiency and minimising wear.

Operation via SlurryMaster 8000 provides maximum comfort. A series of automatic functions protects the system against incorrect use and simplifies operation for the driver. The centrifugal pump stops automatically when the tanker is full and the spade valve below the pump closes. A smart timer function can be activated so the arm lowers automatically into the transport position.

Find more information about the key features of the product.

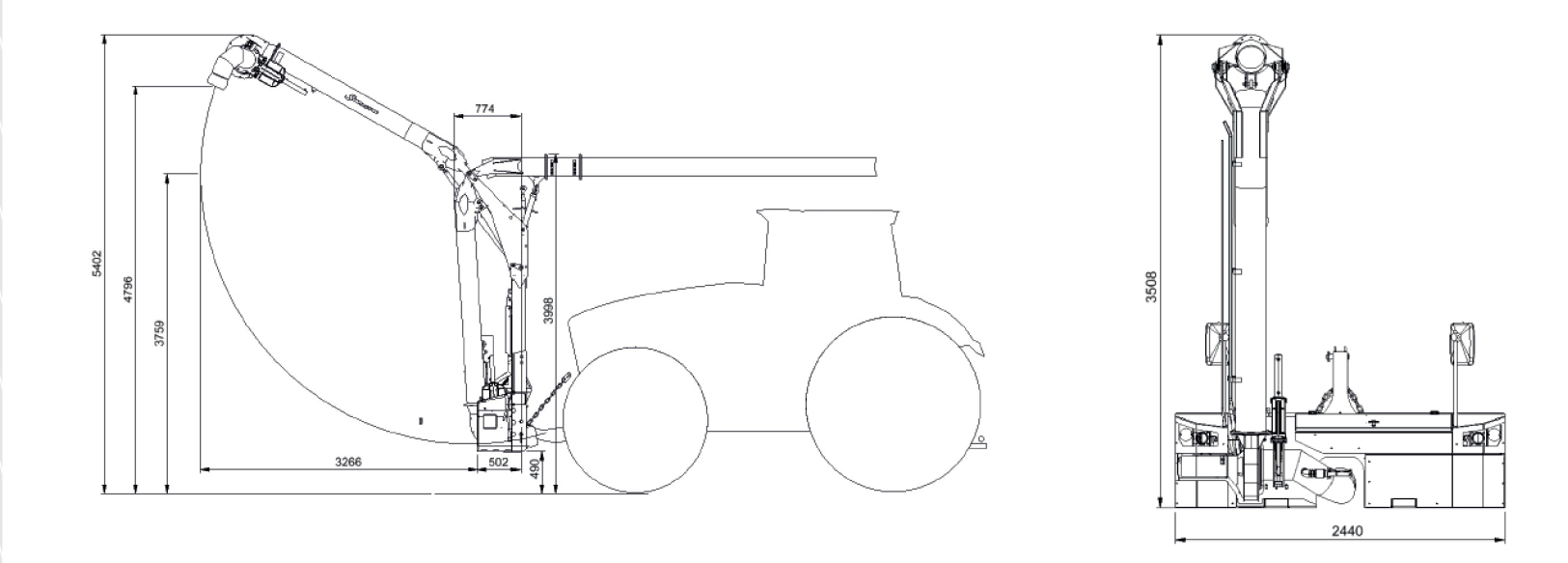

The FAP system has been designed with driver comfort and safety in mind. The fill arm is mounted on the right hand side to ensure that the driver has maximum visibility. The integrated lights are well protected and provide optimal lighting.

Integrated mirrors and camera system are offered as optional accessories.

The FAP system can easily be connected and disconnected by one person without the use of lifting equipment.

The filling pipe can easily be raised clear of the tractor using the integrated hand pump in the storage compartment.

The integrated stabilizer feet and parking lock ensure that the FAP system is stable when it is disconnected.